The Role of Cylinders in Diesel Engine Excavators

Time:

2023-09-18

Diesel engine excavators are powerful and versatile machines commonly used in construction, mining, and excavation projects. These excavators rely on a combination of mechanical and hydraulic systems to perform tasks such as digging, lifting, and moving heavy materials.

Diesel engine excavators are powerful and versatile machines commonly used in construction, mining, and excavation projects. These excavators rely on a combination of mechanical and hydraulic systems to perform tasks such as digging, lifting, and moving heavy materials. At the heart of the diesel engine excavator is the engine itself, which contains a crucial component known as the cylinder. In this comprehensive article, we will explore the role of cylinders in diesel engine excavators, their types, and their significance in the overall performance of these heavy-duty machines.

The Basics of Diesel Engine Excavators:

Before delving into the role of cylinders, let's briefly understand how diesel engine excavators operate:

1. Diesel Engine: The excavator is powered by a diesel engine, which converts the chemical energy in diesel fuel into mechanical energy. This mechanical energy drives various components of the excavator, enabling it to perform tasks.

2. Hydraulic System: Excavators use hydraulic systems to control the movement of their arms, buckets, and other attachments. Hydraulic fluid is pressurized and directed to hydraulic cylinders, which generate force to move these components.

3. Boom and Arm: The boom is the long, horizontal structure of the excavator that extends from the main body. The arm is attached to the end of the boom and supports the bucket or other attachments.

4. Bucket or Attachments: The bucket is the primary attachment used for digging, but excavators can be equipped with various other attachments, such as grapples, hammers, or shears, for different tasks.

The Role of Cylinders in Diesel Engine Excavators:

Cylinders play a critical role in diesel engine excavators, primarily in the hydraulic system. Hydraulic cylinders are mechanical actuators that convert hydraulic pressure into linear motion. Here's how cylinders contribute to the excavator's functionality:

1. Bucket and Attachment Movement:

One of the primary functions of hydraulic cylinders in excavators is to control the movement of the bucket or other attachments. When hydraulic fluid is pressurized and directed to the cylinders, it pushes a piston inside the cylinder, generating linear motion. This motion extends or retracts the cylinder's rod, which is connected to the arm or attachment, allowing for precise and powerful movement.

- Digging: When the operator commands the excavator to dig, hydraulic fluid is directed to the cylinders connected to the bucket's arms. This extends the cylinders, lowering the bucket into the ground and allowing it to scoop up material.

- Lifting: To lift and raise heavy materials, hydraulic cylinders extend, lifting the arm and attachment. The operator can control the height and angle of the arm to manipulate the load effectively.

2. Boom Movement:

In addition to controlling the bucket and attachment, hydraulic cylinders are used to manipulate the excavator's boom. The boom's movement is crucial for positioning the bucket or attachment accurately and efficiently.

- Raising and Lowering: Hydraulic cylinders connected to the boom allow it to be raised or lowered. This feature is essential for reaching various depths during excavation and for loading materials onto trucks or into containers.

3. Rotating the House:

Many excavators feature a rotating house or upper structure that allows the operator to rotate the entire upper part of the excavator. This rotation is achieved through the use of hydraulic cylinders, which turn the house on its base. This feature is particularly useful for accessing different areas without moving the entire machine.

Mitsubishi L3E Diesel Engine Motor

Types of Hydraulic Cylinders in Excavators:

There are several types of hydraulic cylinders used in diesel engine excavators, each serving specific purposes:

1. Boom Cylinders: Boom cylinders are typically the largest hydraulic cylinders on an excavator. They control the movement of the boom, allowing it to be raised, lowered, and positioned at different angles.

2. Arm Cylinders: Arm cylinders are connected to the arm of the excavator and are responsible for controlling the arm's movement. They enable the arm to extend and retract, allowing for precise digging and lifting.

3. Bucket Cylinders: Bucket cylinders are attached to the bucket and control its movement. These cylinders extend or retract to open or close the bucket, enabling digging and material handling.

4. Swing Cylinders: Swing cylinders are responsible for rotating the upper structure or house of the excavator. They allow the operator to pivot the house to the desired position.

5. Track or Travel Cylinders: Track or travel cylinders control the movement of the tracks or wheels on the excavator, enabling it to move forward, backward, or turn.

Significance of Cylinder Performance:

The performance of hydraulic cylinders in diesel engine excavators is crucial for several reasons:

1. Efficiency: Well-functioning cylinders ensure that excavators operate efficiently, allowing operators to complete tasks quickly and accurately.

2. Precision: Precise control of cylinders is essential for delicate operations, such as fine digging or lifting fragile materials.

3. Safety: Properly maintained cylinders contribute to the safety of the excavator, preventing unexpected failures or accidents during operation.

4. Productivity: Efficient cylinders enhance overall productivity, allowing operators to complete more work in less time.

5. Durability: Cylinders that are designed for durability and can withstand the rigors of heavy-duty excavation contribute to the long lifespan of the excavator.

Conclusion

Cylinders are fundamental components of diesel engine excavators, playing a central role in controlling the movement of the boom, arm, bucket, and attachments. Their ability to generate powerful and precise linear motion through hydraulic pressure is critical for the excavator's functionality. Proper maintenance and care of hydraulic cylinders are essential to ensure the excavator operates efficiently, safely, and productively, making them indispensable components in the world of construction and excavation.

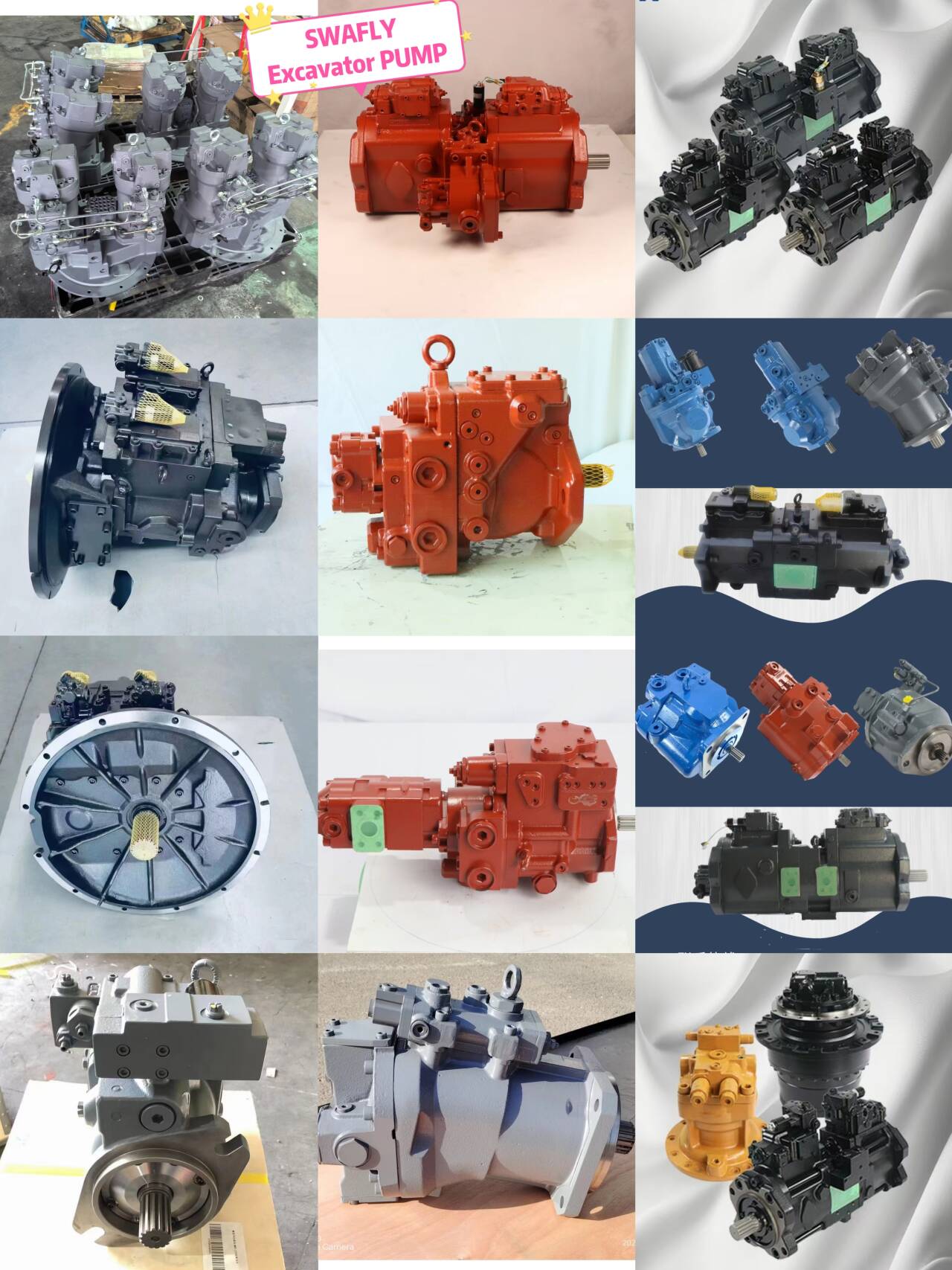

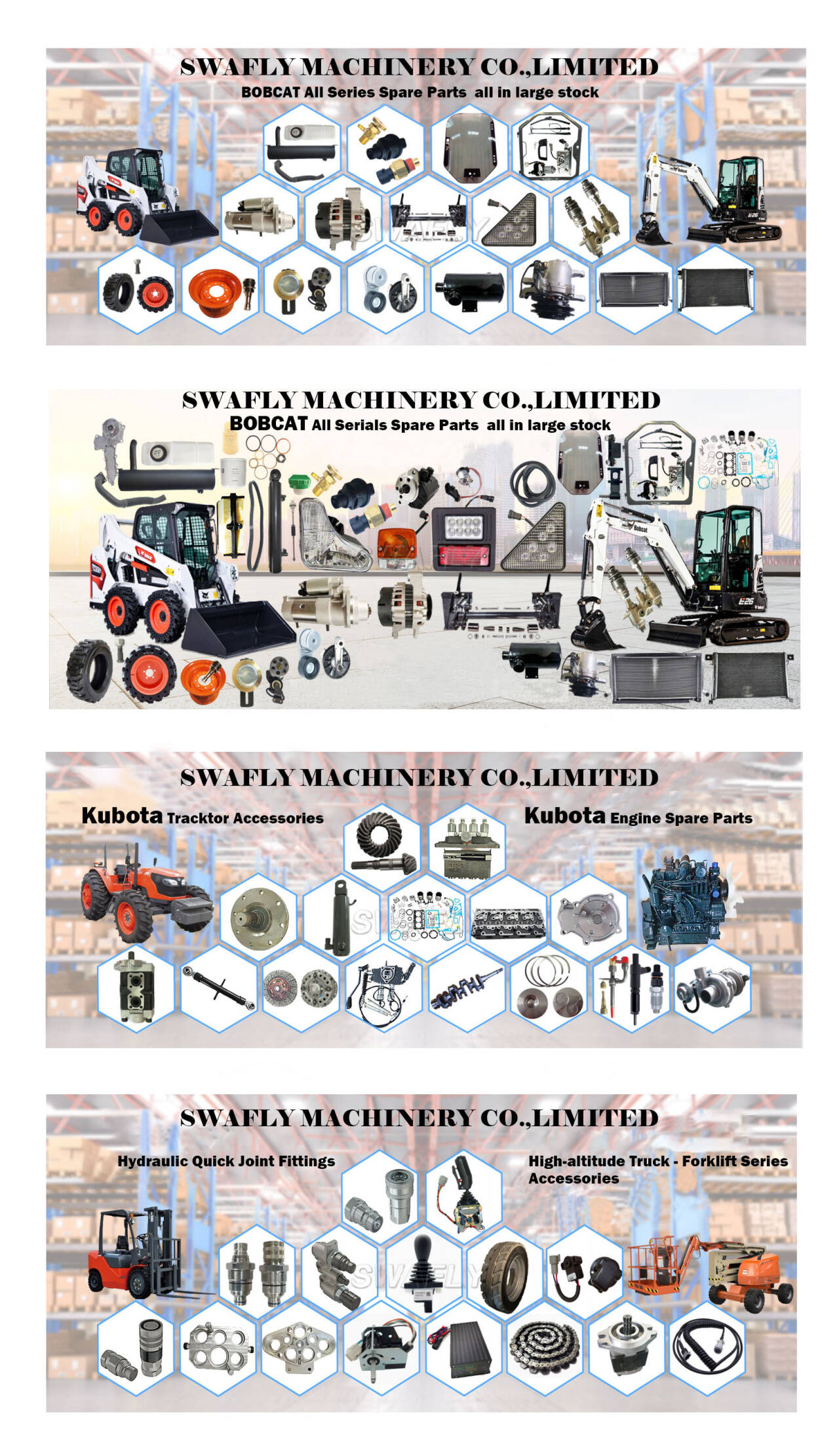

SWAFLY MACHINERY CO., LIMITED specializes in excavator parts and mining equipment parts in China. Founded in 2009, we can supply a quality-trusted full range of machinery engines, hydraulic pumps, and travel final motor drives based on more than 15 years of endeavor and experience. And we also provide agricultural tractor machinery engines with KUBOTA and Yanmar brands.

If you want to know more information about windows, please click on the image below to get a free quote:

More News