Excavator Engines: Understanding the Power and Complexities of Diesels in Small Excavators

Time:

2024-01-22

Diesel engines stand as the powerhouse for small excavators, providing them with the robustness needed to tackle various tasks. Unlike their gasoline counterparts, diesel engines are known for their efficiency and durability, making them the preferred choice for heavy-duty machinery.

In the realm of construction machinery, small excavators play a pivotal role in executing precision tasks. At the heart of these workhorses lie the engines, specifically diesel engines. In this article, we delve into the intricacies of excavator engines, exploring their power, complexities, and the unique features that set them apart.

Unveiling the Power: The Heart of Small Excavators

The Dominance of Diesel

Diesel engines stand as the powerhouse for small excavators, providing them with the robustness needed to tackle various tasks. Unlike their gasoline counterparts, diesel engines are known for their efficiency and durability, making them the preferred choice for heavy-duty machinery.

Power to Size Ratio

One remarkable aspect of excavator engines is their impressive power-to-size ratio. Small excavators equipped with diesel engines can generate substantial power relative to their compact frames. This efficiency ensures optimal performance in tight spaces without compromising on power output.

Kubota V3300 Engine 2600RPM Engine Motor Assembly

Navigating the Complexities: Understanding the Intricate Components

Turbocharging Technology

One of the key complexities in excavator engines lies in the integration of turbocharging technology. This innovation enhances engine performance by forcing more air into the combustion chamber, resulting in increased power output without a significant increase in engine size.

Common Rail Fuel Injection

The intricacies of diesel engines extend to their fuel delivery systems. Small excavators often feature common rail fuel injection, a cutting-edge technology that allows for precise control over fuel delivery, optimizing combustion efficiency and reducing emissions.

Maintenance Considerations: Prolonging the Lifespan of Excavator Engines

Regular Inspection and Servicing

To ensure the longevity of excavator engines, regular inspection and servicing are paramount. Routine checks on components such as the fuel injectors, turbocharger, and cooling system can prevent issues and maintain optimal performance.

Lubrication Systems

Proper lubrication is a critical factor in preserving the health of excavator engines. Well-designed lubrication systems ensure that all moving parts are adequately lubricated, reducing friction and minimizing wear and tear.

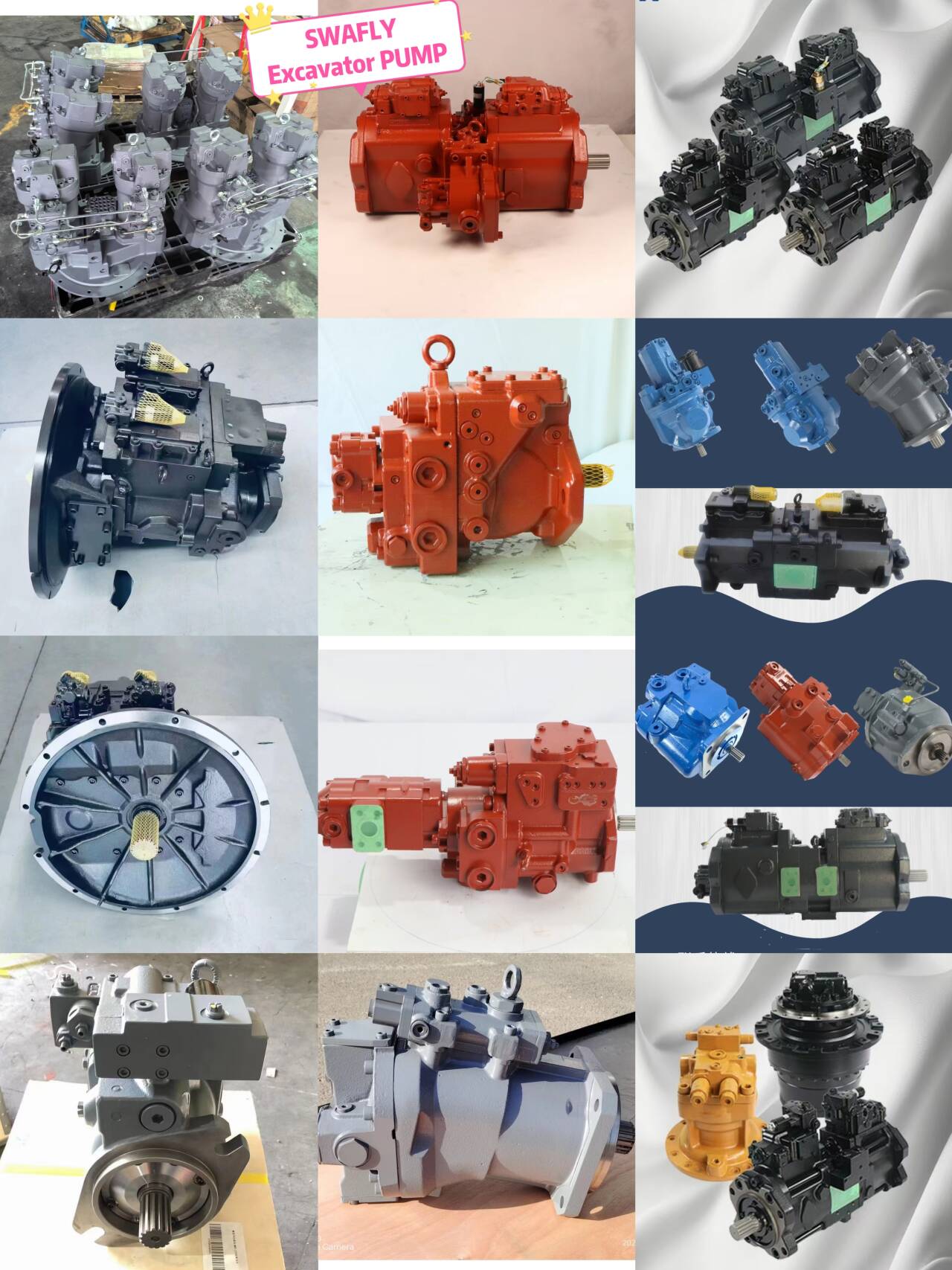

Choosing the Right Supplier: Ensuring Quality Excavator Engines

Reputation and Reliability

When it comes to procuring excavator engines, selecting the right supplier is crucial. Reputable suppliers with a track record of providing reliable and high-performance engines should be prioritized.

Customization Options

A top-tier supplier understands that each construction project has unique requirements. Offering customization options ensures that the excavator engine aligns perfectly with the specific needs of the customer, enhancing overall project efficiency.

Conclusion: Empowering Your Excavation Projects

In conclusion, understanding the power and complexities of diesel engines in small excavators is pivotal for making informed decisions in the construction industry. The dominance of diesel, coupled with technological advancements like turbocharging and common rail fuel injection, elevates the performance of these machines. Regular maintenance and choosing a reputable supplier further contribute to the reliability and longevity of excavator engines.

If you are ready to empower your construction projects with high-quality excavator engines, contact us today to explore our range of top-notch products. As your dedicated supplier, we are committed to delivering engines that meet your specifications, ensuring optimal performance on every job site.

More News